Reaction Resin Mortar Based on Vinylester Styrene-Free Resin

TP VSF mortar is a 2-component reaction resin mortar based on a vinylester resin styrene-free and will be delivered in a 2-c cartridge (ST – Standard cartridge; PM – Pre-Mix cartridge; SF – Foil Tube cartridge) system. This high performance product may be used in combination with a hand-, battery-or pneumatic tool and a static mixer. It was designed especially for the anchoring of threaded rods, reinforcing bars or internal threaded rod sleeves into concrete (also porous and light) as well as masonry. Based on the excellent standing behavior, the usability in combination with a special plastic sleeve in hollow material is given. TP VSF mortar product is characterized by a huge range of applications with an installation temperature from -10°C and an application temperature up to 80°C, as well as by high chemical resistance for applications in extreme ambiences, e.g. in swimming pools (chlorine) or in closeness to the sea (salt). The wide range of certificates, as well as national and international approvals, allows nearly every application.

Item Number + Size

TP 1124-2 Size: 420ml

Properties and Benefits

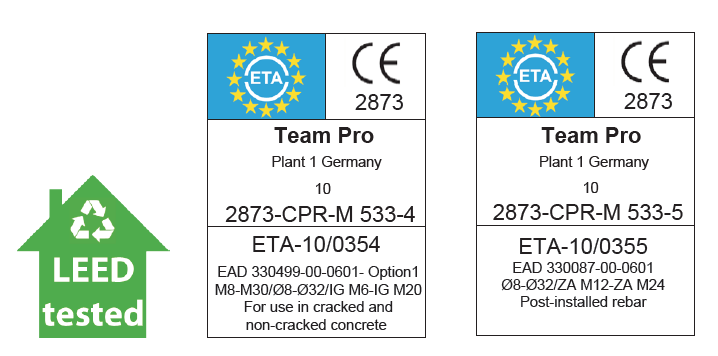

- European Technical Assessment for use in concrete: ETA-10/0354

- European Technical Assessment for post installated rebar: ETA-10/0355

- Certificated for drinking water applications acc. to NSF Standard 61

- For heavy anchoring – doweling and post-installed rebar connection

- Fire resistance test report: EBB 170019_15en

- National approval in masonry

- Overhead application; water-filled bore holes

- Suitable for attachment points with small-edge and axial distances due to an anchoring free of expansion forces

- High chemical resistance

- Low odour

- High bending and pressure strength

- Cartridge can be reused up to the end of the shelf life by replacing the static mixer or resealing cartridge with the sealing cap

Suitable for the fixation of facades, roofs, wood constructions, metal constructions; metal profiles, columns, beams, consoles, railings, sanitary devices, cable trays, piping, post-installed rebar connection (reconstruction or reinforcement), etc.

- Underground:

Cracked and non-cracked concrete, light concrete, porous concrete, solid masonry, hollow brick, natural stone (Attention: natural stone, can discolour; shall be checked in advance); hammer-drilled holes (hollow material shall be drilled without hammer-drilled mode)

- Anchor Elements:

Threaded rods (zinc plated or hot dip, stainless steel and high corrosion resistance steel), reinforcing bars, internal threaded rods, profiled rod, steel section with undercuts (e.g. perforated section)

- Temperature Range:

Installation temperature: -10°C up to +40°C

Cartridge temperature: min. +5°C; optimal +20°C

Base material temperature after full curing: -40°C to +120°C