Reaction Resin Mortar Based on Epoxy Acrylate

TP EA is a 2-component reaction resin mortar based on an epoxy acrylate. This product may be used in combination of a hand-, battery- or pneumatic tool and a static mixer. It was designed as a cost-effective alternative for the anchoring of threaded rods and internal threaded rod sleeves for approved applications. By using a screen sleeve, an easy and safe application in hollow bricks is guaranteed.

TP EA product is characterized by good applications with an ambiance temperature up to 80°C.

Item Number + Size

TP 1115-2 Size: 300ml

Properties and Benefits

- European approval in concrete ETA 13/0678

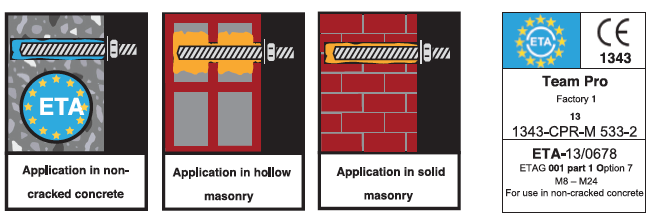

- Application in uncracked concrete, solid brick, and hollow brick with commercial threaded rods

- Overhead application

- Suitable for attachment points close to the edge, since anchoring is free of expansion forces

- Reduced chemical resistance

- High bending- and pressure strength

- Cartridge can be reused up to the end of the shelf life by replacing the static mixer or resealing cartridge with the screw cap

- Mechanical properties acc. to EN 196 Part1

– Density: 1,66 kg/dm2

– Compressive strength: 108 N/mm2

– Bending strength: 56 N/mm2

– Dynamic modulus of elasticity: 3300 N/mm2

Suitable for the fixation of facades, roofs, wood constructions, metal constructions metal profiles, console, railing, sanitary devices, cable trays, piping, etc.

- Underground:

Non-cracked concrete, light concrete, porous concrete, solid masonry, hollow brick, natural stone

(Attention: natural stone, can discolour; shall be checked in advance); hammer-drilled holes

- Anchor Elements:

Threaded rods (zinc plated or hot dip, stainless steel and high corrosion resistance steel), reinforcing bars,

internal threaded rods, profiled rod, steel section with undercuts (e.g. perforated section)

- Temperature Range:

Installation temperature: 5°C up to +35°C

Cartridge temperature: min. +5°C; optimal +20°C

Base material temperature after full curing: -40°C to +80°C